Answer

Feb 02, 2026 - 08:49 PM

Bonding Agents are mainly for Ceramic Tile and Porcelain, All Other Surfaces like ABS Plastic, Fiberglass, Cultured Marble , Formica, the BULL SHARK is best. They are different surfaces. They Flex more. Bull Shark leaves a microscopic film that seals the surface plus allows flexibility. For Porcelain and Ceramic Tile Use this Power Bond Wipe On Primer for Porcelain Bathtubs

![[EAH INDUSTRIAL]](https://data3.answerbase.com/answerbase/14455/Images/answerbase.brands.header3 (1).png?638469925900000000)

By

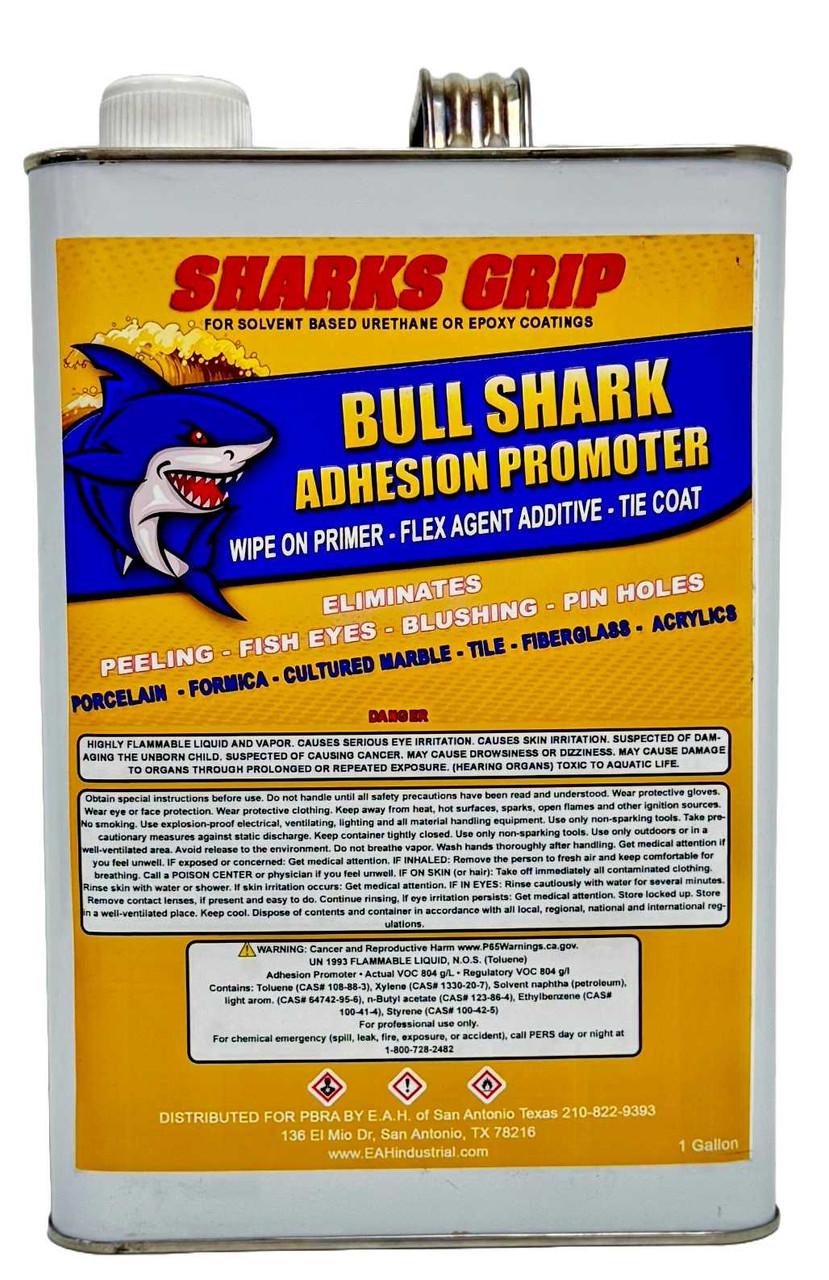

Bull Shark Adhesion Promoter & Fisheye Blocker

Bull Shark is one of those rare products every refinisher should always have on the truck. It’s compatible with any solvent-based coating system and solves more job-site problems than almost anything else you can spray or wipe on.

At the microscopic level, Bull Shark acts like a fiberglass web fused with a high-strength bonding agent, leaving behind an ultra-thin, flexible, invisible film. Once applied, you are no longer spraying the surface — you are spraying over Bull Shark’s controlled, chemically stable layer.

That matters because most real-world failures don’t come from bad spraying — they come from what you can’t see:

Traces of silicone

Wax residues

Body oils

Grease from Formica and backsplashes

Contaminants embedded in fiberglass or cultured marble

Even after degreasing, sanding, and solvent wiping, those invisible residues can still cause:

Fisheyes

Blushing

Cratering

Pinholes

Repelling

Bull Shark locks all of that down.

Pinholes & Cultured Marble

Cultured marble is notorious for micro-porosity. Those tiny voids are where pinholes are born. Bull Shark fills and seals them before topcoat ever hits, eliminating the most common cause of callbacks on these surfaces.

Formica & Greasy Surfaces

Formica counters and backsplashes trap oils deep in the surface. Even after aggressive cleaning and sanding, fisheyes can still appear. Bull Shark creates a new, uncontaminated surface so your coating bonds cleanly and evenly.

Instant Fisheye Repair – No Recoat Day Needed

One of the biggest reasons pros love Bull Shark is the spray-can rescue method:

If a fisheye or blush pops up while spraying:

Use your turbine hot air to dry that area for about a minute

Spray Bull Shark directly onto the defect

Turbine-dry again

Resume spraying your topcoat

The fisheye disappears — no sanding, no stripping, no return trip.

And every refinisher knows the truth:

You can do a flawless job… but the customer will only see that one tiny fisheye.

Bull Shark prevents that moment.

Flex Agent Built In

Bull Shark is also a powerful flex additive.

By substituting just 1 ounce per cup of your coating, you double the flexibility of the film.

That’s critical on:

Fiberglass tubs

Cultured marble

ABS plastics

Laminates

Any surface exposed to thermal expansion, vibration, or flex

Without flexibility, coatings crack. Bull Shark keeps them bonded and moving together.

Bottom line:

Bull Shark doesn’t just prevent problems — it creates a chemically clean, flexible, stable surface that lets your coatings perform the way they were designed to.

It saves jobs.

It saves callbacks.

It saves reputations.

And that’s why pros keep it on the truck — in quarts and spray cans

Add New Comment